Spatial Excellence award for Land Solution Australia and UPG

Last year, Land Solution Australia and UPG were awarded an innovation and commercialisation award at the Queensland Spatial Excellence awards for their work on the Southpoint development in Brisbane.

Last year, Land Solution Australia and UPG were awarded an innovation and commercialisation award at the Queensland Spatial Excellence awards for their work on the Southpoint development in Brisbane.

Land Solution Australia were contracted by Watpac to monitor existing assets – a railway corridor, bus tunnel and an historic building – and to do this they turned to UPG to work together on a solution.

The Pulse of Brisbane

Innovative software and communications help to safeguard a complex construction project.

In the heart of Australia’s third most populous city, Watpac Australia Pty. Ltd. has a contract to build Southpoint Development, a $650 million project that will integrate residential, commercial, hotel and public space with a public transport hub. The work must be completed without damaging three pre-existing assets—a busy railway corridor, a bus tunnel and an historic building. This required a solution to monitor the work in real time and alert stakeholders to any deformation that could lead to a collapse and endanger lives. “Our goal was to provide a level of assurance that there was no effect on the tunnel or the rail line,” says Dave McIlwraith, a Watpac project manager.

Land Solution Australia Pty. Ltd. devised a solution that included total stations, geotechnical sensors and a complex communication system to feed the data to Watpac’s Trimble® 4D Control software platform. “This solution collected different data types, managed them in near real time via a secure central server, and allowed users the ability to analyse or combine the data in a variety of ways for different purposes,” said Lee Hellen, a professional surveyor and Land Solution’s director. “We relied heavily upon the equipment and expertise of our technology partners—UPG, Saros, ES&S and Runge ICT—to provide the vibration and geotechnical sensors and IT knowledge.”

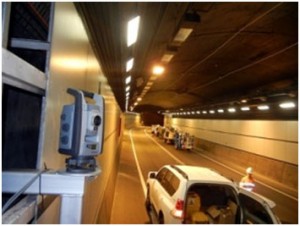

Land Solution attached 36 monitoring prisms to the tunnel’s capping beam and lining and 102 prisms to the tracks. They installed a Trimble S8 total station in the tunnel, another on an adjoining building, and about 20 geotechnical sensors. “One of the challenges was that we were trying to deliver a monitoring system while construction had commenced,” said Simon Sprague, a geospatial technical consultant with UPG.

Land Solution attached 36 monitoring prisms to the tunnel’s capping beam and lining and 102 prisms to the tracks. They installed a Trimble S8 total station in the tunnel, another on an adjoining building, and about 20 geotechnical sensors. “One of the challenges was that we were trying to deliver a monitoring system while construction had commenced,” said Simon Sprague, a geospatial technical consultant with UPG.

The project called for geotechnical and survey observations with 24-hour automated alarming whenever engineering design tolerances were exceeded. The work required expertise in surveying, vibration, communications and IT. For example, the system issues a warning if the survey tolerances in the tunnel are exceeded by 0.5 mm and an alarm if they are exceeded by 2 mm. Therefore, vertical angle refractions had to be corrected for variations in the tunnel’s temperature throughout a 24-hour cycle. To solve this problem, the team isolated some of the alarms at different times of night at different times during the project and the tunnel operators ran the fans 24 hours rather than just during the day.

Two additional challenges were the extent of the communications required to reliably serve the data up to the customer in real time and liaising with the many parties involved.

Delivering and Analysing the Data

The sensors connected to an outside server running Trimble 4D Control software (T4D). The data was served up to the client via a Web user interface, desktop software and SMS and e-mail messages. Sending data directly from the total station in the tunnel to the server by radio could be problematic. Instead, the data travelled to an adjacent communication box where it was converted to TCIP/IP format and then sent through about 100 m of Ethernet cable to a radio positioned to get a good signal to another radio located about 150 m away from the server. The second total station, installed on top of a 15-story building, had a direct radio link to the server. Three on-site field data loggers used GSM modems to send the data to an on-site server and 900-MHz radio connections control the total stations through a Trimble Pivot software platform.

Watpac engineers accessed the monitoring data via a Web user interface from the T4D software. They could control the alarm levels and recipients, analyse the data, and plot various data types against each other. The geotechnical data was sent via the 3D data connection to a server, where the T4D software automatically processed the data and produced the analysis.

Watpac engineers accessed the monitoring data via a Web user interface from the T4D software. They could control the alarm levels and recipients, analyse the data, and plot various data types against each other. The geotechnical data was sent via the 3D data connection to a server, where the T4D software automatically processed the data and produced the analysis.

Each day, the survey equipment delivered 8,400 measurements and the environmental and geotechnical sensors delivered possibly tens of thousands of observations, all accessible via the Web portal. “We were using the data daily to monitor during the excavation, because things were moving,” said McIlwraith.

The monitoring data was analysed in real time by the Trimble Pivot Platform. Land Solution Australia configured T4D to include standard reports and to allow the engineers to customise them. “Our job was to provide high quality reliable data to the engineers so that they can interpret it,” Sprague said. Users could also directly query the T4D database using SQL.

The Value of Innovation

“We had to deal with the constraints of a live project, with very busy public transport utilities always being utilised,” said UPG’s Rodd Yann. This environment enabled Land Solution Australia to create a fully automated geospatial ecosystem, requiring a solid understanding of the project’s evolution. The project was innovative in that it utilised geotechnical sensors as well as conventional surveying tools. It was also critical to put in place a good IT infrastructure and for the team to have good relationships with all the parties involved. Overall management of the solution by a professional surveyor committed to the needs of his client was critical for the successful delivery of the project.

By collecting and serving a variety of geospatial and geotechnical data that the client can combine and analyse, the Southpoint project provides a model for how to monitor complex and dynamic work sites.