Overview

Road surveying safety and efficiency challenges.

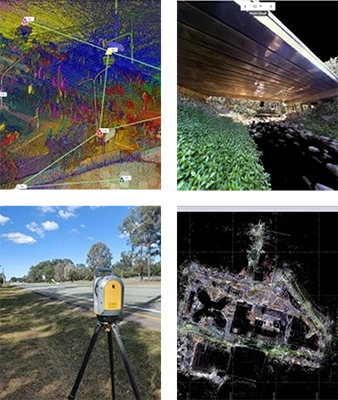

Road surveying safety and efficiency challenges are a common concern when working on busy roads, often requiring nighttime work and expensive traffic control measures. A recent incident highlighted the need for safer solutions. Additionally, RPS faced limitations with the SX Series’ slow scan times and the X Series’ accuracy issues on long linear projects, emphasising the need for more efficient methods.

About RPS

RPS, a division of Tetra Tech, has transformed its road pavement survey workflows by incorporating cutting-edge terrestrial laser scanning technologies. Damian Ling, Technical Director and Strategy Lead for Geospatial Solutions at RPS, brings over 20 years of surveying experience with a focus on using technology to enhance efficiency, safety, and client results, especially in complex road survey conditions.