Overview

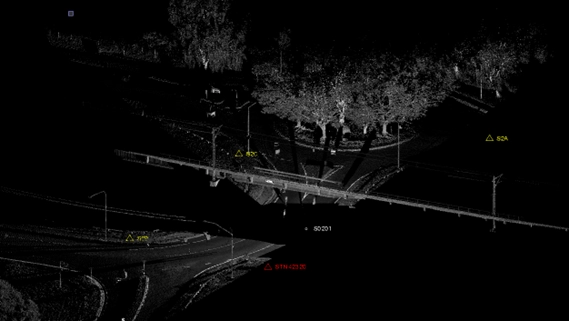

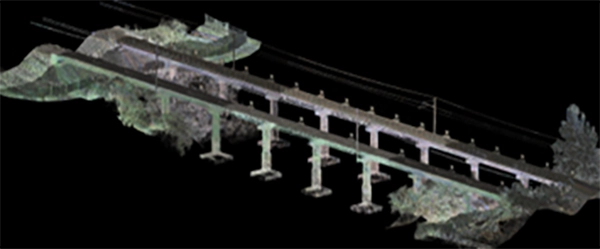

This case study details the experience of NorthGroup Consulting in leveraging the Trimble SX12 scanning total station to overcome significant challenges in large-scale mobile laser scanning (MLS) projects within rail corridors. It highlights how this innovative solution drove new heights in efficiency, data quality, and safety standards, particularly when NorthGroup Consulting was faced with stringent accuracy requirements and difficult site access.

About NorthGroup Consulting

NorthGroup Consulting, based in Stafford, Qld, and formerly North Surveys (est. 1984), has evolved into one of Queensland’s largest surveying firms. The company thrives on complex projects, offering innovative Surveying, Mapping, and Data Management solutions; its core mission is to deliver high-accuracy data efficiently while adhering to the strictest safety protocols. A key strength lies in its leadership in 3D Laser Scanning technology, where NorthGroup Consulting constantly develops advanced methodologies. This commitment to practical innovation in demanding survey environments, as demonstrated by industry recognition, underpins its success.