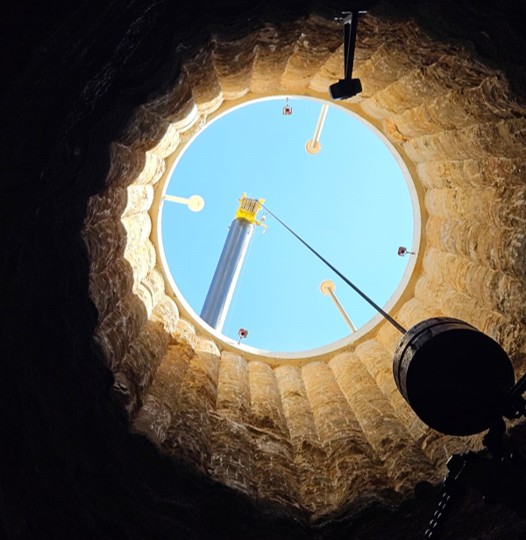

After multiple brainstorming sessions, the team developed a solution for accurately scanning the 254m vertical cable shaft. They established primary control points around the top of the ring beam, offset slightly to remain visible down the shaft’s entire depth. Additionally, they installed secondary control points inside the shaft using a 250ft crane and man basket.

With these control measures in place, the team successfully captured accurate, geo-referenced scan data. The data was processed in real-time on the Trimble TSC7, allowing for on-the-fly planning of each subsequent scanner setup. This approach eliminated guesswork and significantly reduced issues caused by scan shadows.

The team fabricated a custom bracket to securely mount the Trimble SX12 Total Station to the shaft walls. They conducted the scan from the bottom up, using conventional resection methods at each location, and monitoring targets to ensure consistency.

By carefully overlapping full-dome scans, the team ensured seamless alignment during post-processing. They alternated brackets on either side of the shaft to mitigate the SX12’s downward scanning limitations. In just three shifts, the entire shaft was successfully scanned, and ready for data delivery.

Using Trimble Business Centre, the team processed the scan data to generate cross-section comparisons between the as-built conditions and design models. These outputs, delivered in multiple formats, gave the design team the precise information needed to finalise the HV cable bracket and emergency ladderway layout without delay.

Based on this high-accuracy design, the survey team successfully set out the cable shaft bracket system. This enabled the installation crew to align bolt holes and brackets for drilling with ease and confidence, ensuring a quality fit-out.